References energy

Liquid air energy storage

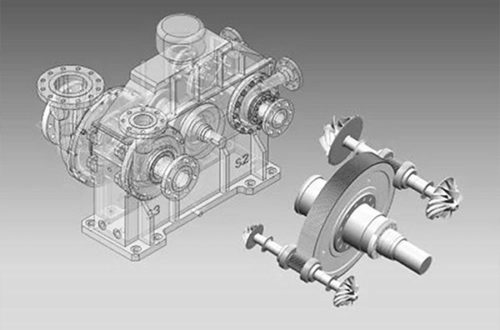

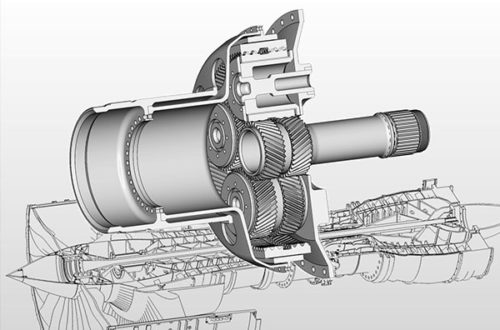

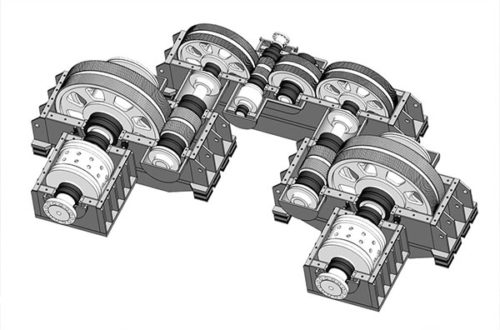

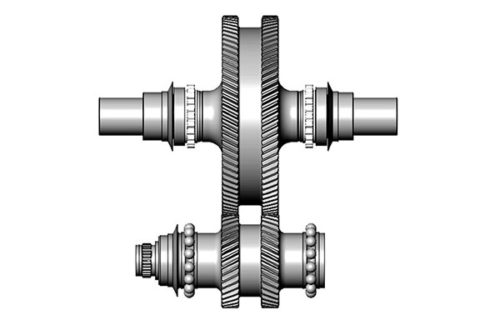

Multi-shaft integral gearbox with thrust collars for a four-stage expander-generator drive.

All four expanders are attached to the gearbox. Each pinion forms an integral part with two impellers.

The thrust collars on the pinions transmit the expander thrusts to the wheel shaft bearings.

Expander speeds: 48’000 and 40’000 rpm.

Number of tooth contacts per second: 24’540.

Hydrogen transport in pipelines

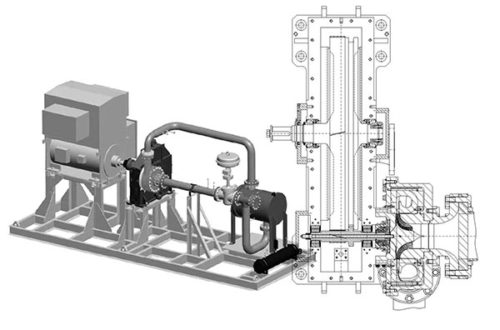

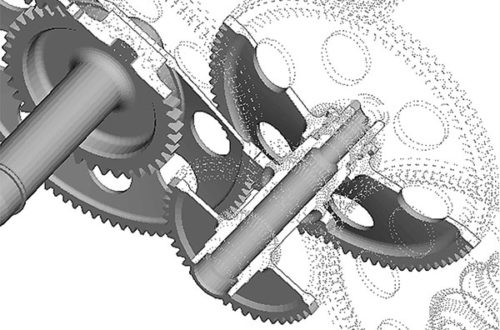

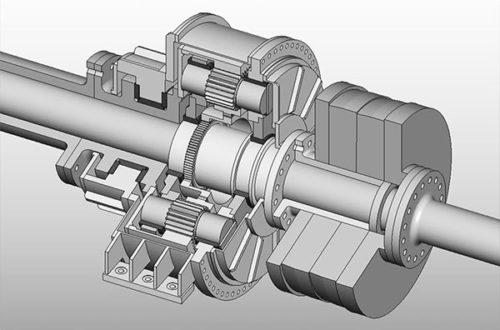

Single-shaft integral gearbox with thrust collar for a motor-compressor drive.

The compressor is attached to the gearbox. The thrust collar on the pinion transmits the compressor thrust to the wheel shaft bearings.

Compressor speed: 60’000 rpm.

Number of tooth contacts per second: 32‘540.

Thrust collar tip speed: 330 m/s.

Turbine generator package

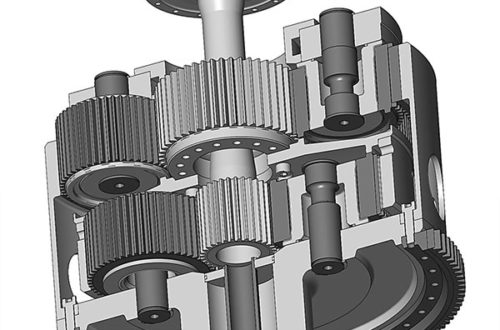

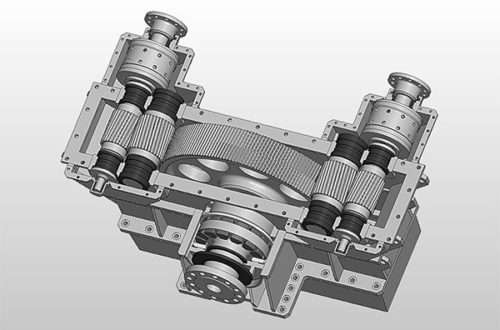

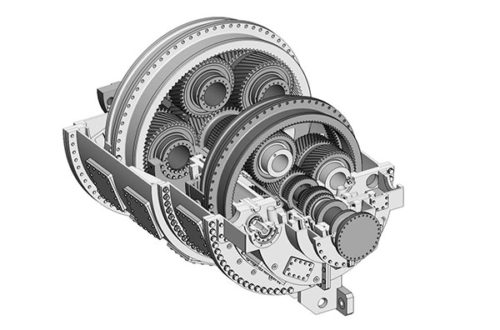

Star-differential epicyclic gearbox for a new type of turbine generator package.

Both gear stages incorporate our flexpin technology for equal load sharing between 5 and 7 planet gears resp. The gearbox includes auxiliary gear drives for turbine starter and pumps.

Turbine speed: 26‘000 rpm.

Gear ratio 14.4:1 and 17.3:1

References aviation

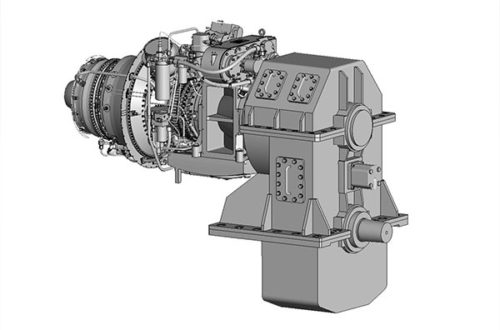

Turboprop engine

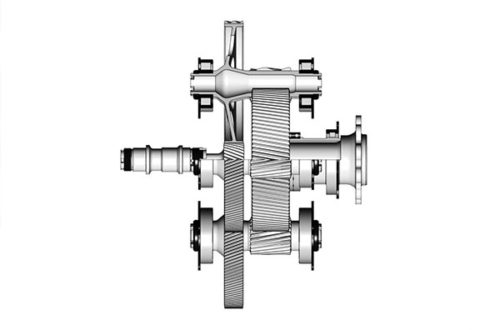

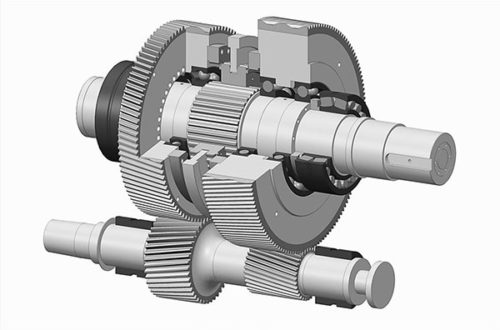

Two-stage parallel shaft gearbox with power split for a turbine-propeller drive.

The variable pitch propeller is flanged directly to the output shaft. The output shaft is designed as a hollow shaft and provides space for the hydraulic control device.

Gear ratio: 1:20.

Power/weight ratio of the gear set: 0.1kg/kW.

Geared turbofan

Single stage planetary gearbox with 5 planet gears for decoupling the fan and the low pressure turbine.

The interfaces as well as the support for the planetary gears are designed to be flexible. It ensures a uniform load distribution over the tooth width and between the planetary gears in any operating condition.

Turbine auxiliary drive

Multi-shaft helical gearbox for the simultaneous drive of oil pump, fuel pump, starter / generator, hydraulic pump and tachometer.

The gear set is weight optimized.

The toothing has a non-standard profile with maximized tooth root rounding and minimized sliding / rolling ratio.

Pitch line velocities 155 and 96 m/s.

References shipbuilding

High-speed ferry

Single stage gearbox with two input shafts and one output shaft for a diesel engine CPP drive (CODAD).

The gearbox transmits the power of both diesel engines to a variable pitch propeller. The motors can be connected or disconnected independently of each other via integrated, hydraulically actuated multi-disc friction clutches.

All shafts and wheels run in white metal journal bearings.

The propeller thrust bearing is integrated in the gearbox and designed as an axial tilting pad bearing.

The OD-box for the propeller is flanged on the forward side of the gearbox.

Power: 2 x 4,400 kW.

Gearbox weight: 19 tons.

Luxury yacht

Combined planetary parallel shaft gear for a gas turbine waterjet drive.

The gas turbine and the gearbox form a compact propulsion unit.

The gearbox is made in lightweight construction with the casing made of aluminum.

A self-synchronizing clutch connects the turbine shaft to the input shaft.

The gearbox is equipped with a PTI for an auxiliary diesel engine.

Turbine power: 4’200 kW.

Gearbox weight: 2.1 tons.

Contra-rotating propeller system

Planetary gear with 7 planetary gears and hollow shaft for a diesel engine CRP drive.

The two propellers are arranged coaxially. The diesel engine drives the aft propeller directly and the forward propeller via the gearbox, which reverses the direction of rotation and reduces the speed.

The thrust bearing for the forward propeller is integrated in the gearbox.

For a uniform load distribution between the planetary gears, the sun gear is self-aligning and the ring gear is flexible.

Output torque: 1’360 kNm max.

Gearbox weight: 54 tons.

References defence

CODLAG System

Two-stage CODLAG gear system for a gas turbine / electric motor propeller drive.

The system consists of a cross-connect gear, which transmits the power of the gas turbine to the two main gears Port and Stbd. Each of the two main gears is connected with the associated propeller Port and Stbd via a hydraulically actuated multi-disc friction clutch. For the electric motor propulsion mode, the complete gear system can be disconnected from the propeller shafts.

In order to minimize transmission of structure-borne noise to the ship's foundation, all gearboxes are supported on double-elastic resilient mounts.

Power of gas turbine: 38’000 kW.

Power of electric motors: 2 x 1'800 kW.

Weight of complete gear system: 114 tons.

Steam turbine propulsion

Two-stage planetary gearbox with double helical gears for a gas turbine propeller drive.

The two planetary stages are double-joint coupled for free radial and axial self-alignment of the wheels. All planet gears are supported by wear-free journal bearings. A turning gear device for maintenance purposes is integrated in the gearbox.

Power: 32’000 kW.

Gearbox length: 3.2 m.

Gearbox weight: 28 tons.

References electromobility

Planetary gear for electric transport vehicle

Technical data:

- Power 175 kW max.

- Input speed: 4'500 - 12'000 rpm (up to 18'000 rpm on request)

- Output torque: 2'600 Nm max.

- Gear ratio: 1:7

- Dry weight: 27 kg

Product features:

- The gear design is modular and can be quickly adapted to individual customer requirements.

- Optional free-hanging or flanged to the electric motor.

- New circulating lubrication system without pump for maximum efficiency.

- Optional with sensors for vehicle condition monitoring.

References test benches

Spin test rig

Single-stage parallel shaft gearbox for two selectable output speeds.

The two switching wheels are supported on a common shaft by means of preloaded roller bearings.

Power: 8’000 kW

Output speeds: 4’500 and 2’200 rpm

Electric motor test bench

Single-stage parallel shaft gearbox with double helical gears and spindle bearings.

The gearbox is designed for varying loads up to zero speed. The powertrain can be operated resonance-free throughout the entire load and speed range.

Output speed: 28’000 rpm

Pitch line velocity: 172 m/s