Shipbuilding

For the shipbuilding sector, we design and develop various types of customized marine gearboxes:

- Gearboxes and gearbox systems for single and multi-engines, such as diesel engine, gas turbine, steam turbine, electric motor

- Gearboxes for hybrid drives

- Gearboxes for contrarotating propellers (CRP)

- Reversing gear units

- Gearboxes with PTO and / or PTI

Our gearbox designs comply with the rules of the classification society chosen by the customer, e.g. DNV-GL, BV, LRS, ABS, RINA, MIL etc.

Features of our gearbox solutions for the shipbuilding sector:

- Compact and lightweight

- Extremely low noise levels

- Crude oil or LNG tanker

- Passenger ships

- High speed ferries

- Yachts / mega-yachts

- Research vessels

Examples of completed customer projects:

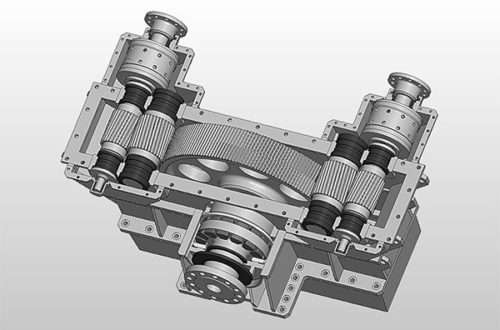

High-speed ferry

Single stage gearbox with two input shafts and one output shaft for a diesel engine CPP drive (CODAD).

The gearbox transmits the power of both diesel engines to a variable pitch propeller. The motors can be connected or disconnected independently of each other via integrated, hydraulically actuated multi-disc friction clutches.

All shafts and wheels run in white metal journal bearings.

The propeller thrust bearing is integrated in the gearbox and designed as an axial tilting pad bearing.

The OD-box for the propeller is flanged on the forward side of the gearbox.

Power: 2 x 4,400 kW.

Gearbox weight: 19 tons.

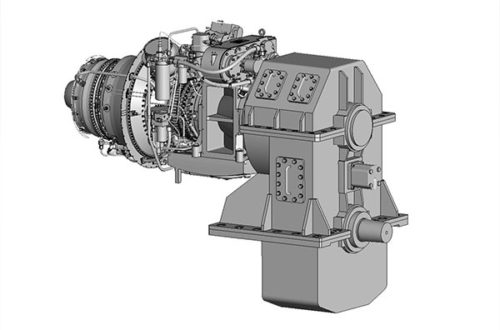

Luxury yacht

Combined planetary parallel shaft gear for a gas turbine waterjet drive.

The gas turbine and the gearbox form a compact propulsion unit.

The gearbox is made in lightweight construction with the casing made of aluminum.

A self-synchronizing clutch connects the turbine shaft to the input shaft.

The gearbox is equipped with a PTI for an auxiliary diesel engine.

Turbine power: 4’200 kW.

Gearbox weight: 2.1 tons.

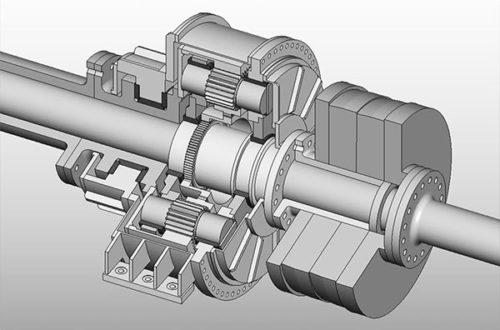

Contra-rotating propeller system

Planetary gear with 7 planetary gears and hollow shaft for a diesel engine CRP drive.

The two propellers are arranged coaxially. The diesel engine drives the aft propeller directly and the forward propeller via the gearbox, which reverses the direction of rotation and reduces the speed.

The thrust bearing for the forward propeller is integrated in the gearbox.

For a uniform load distribution between the planetary gears, the sun gear is self-aligning and the ring gear is flexible.

Output torque: 1’360 kNm max.

Gearbox weight: 54 tons.