News

15th anniversary

NOVAGEAR celebrates its 15th anniversary. A big thank to all our customers partners and friends for your trust and loyalty. Andre Thuswaldner

A nimble climber – magnecko

A team of 8 students at the Swiss Federal Institute of Technology Zurich (ETH Zurich) has successfully demonstrated a quadruped robot in 2023. It can assist industrial workers with inspection and repair on tall ferromagnetic structures. The robot uses electro-permanent magnet modules on its feet, allowing it to climb on walls and even upside-down on…

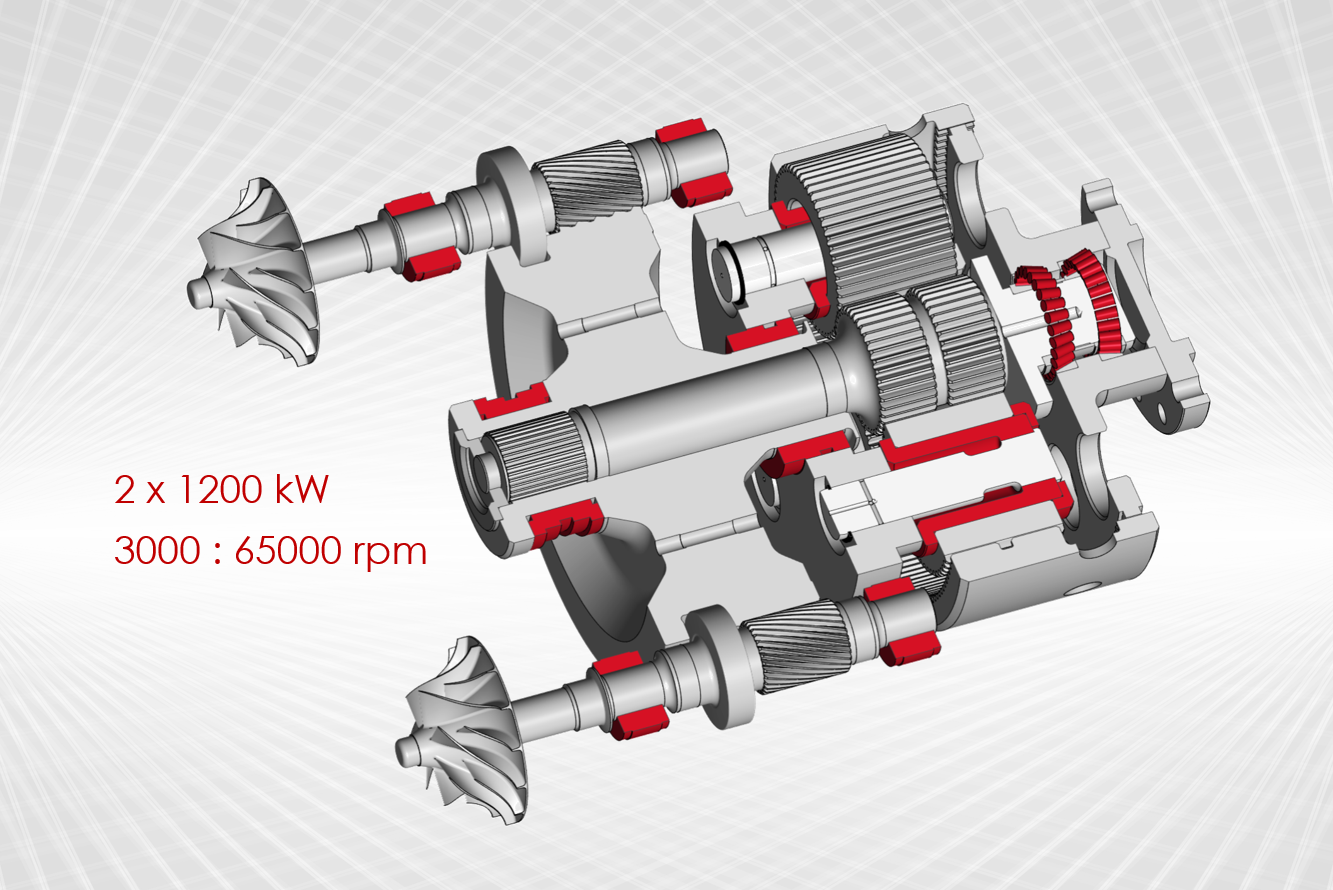

Sprinting Cheetah!

Our newest design highlight in 2023 – an integral gear unit with maximized compactness and minimized weight. Transmitted power 2 x 1200 kW @ 65000 rpm compressor speed. Impeller thrust forces are transferred to the low-speed shaft bearings via solid thrust collars. A planetary gear stage with flexible pins reduces the bull gear diameter by…

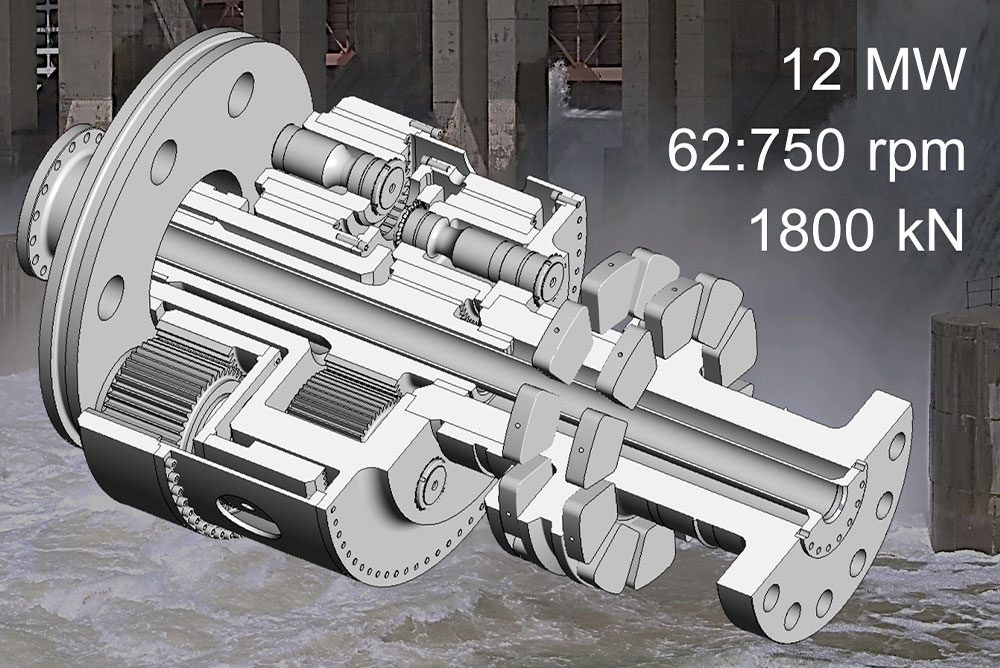

Gear solution for hydro- electric power plant

A consortium, consisting of several European companies, was commissioned to modernize a run-of-the-river hydroelectric power plant in Central Europe. The new machine group, consisting of a 12 MW Kaplan turbine and generator, required a speed increasing gearbox with an integrated turbine thrust bearing. Installation space was limited – a conventional single-stage planetary gearbox with approx.…

Gear solution for hydro- electric power plant

A consortium, consisting of several European companies, was commissioned to modernize a run-of-the-river hydroelectric power plant in Central Europe. The new machine group, consisting of a 12 MW Kaplan turbine and generator, required a speed increasing gearbox with an integrated turbine thrust bearing. Installation space was limited – a conventional single-stage planetary gearbox with approx.…

10th anniversary

NOVAGEAR celebrates the 10th anniversary. A big thank to all our customers and partners for your trust and loyalty. Andre Thuswaldner

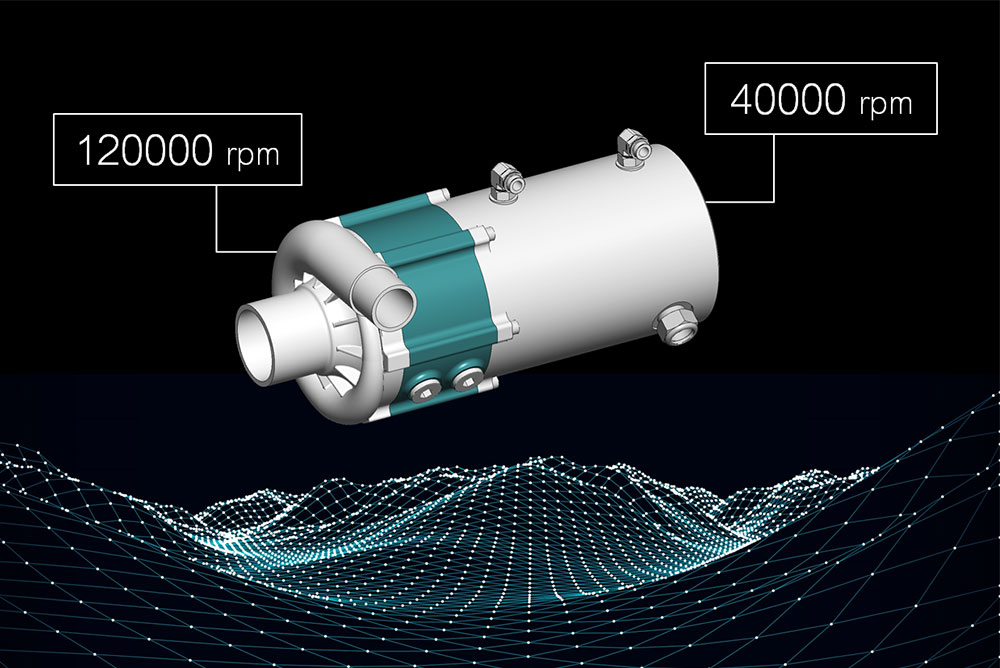

Maximized Efficiency for 48V WHR

Our newest gearbox development for a 48V WHR prototype comprises a minimum quantity lubrication for the gears. The lube oil is precisely dispensed, dependent on speed and temperature, and directed to the gear flanks in atomized condition. With this adaptive lubrication concept, drag and churning losses are reduced by more than 90 percent, compared to…

Milestone in High-Speed

A European turbine manufacturer entrusted NOVAGEAR with the development and design of a test bench gearbox. The nominal speed of 56’000 rpm posed great challenges to the design as well as to the manufacturing. With a triple path power split concept, the gear mesh velocity could be limited to less than 200 m/s. A total…

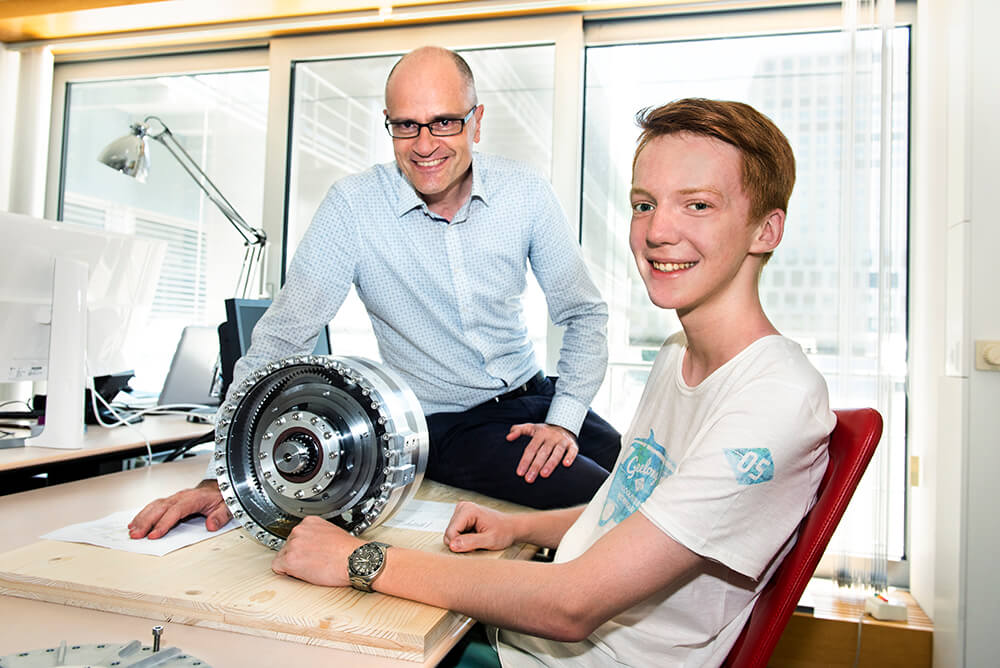

Internship at NOVAGEAR AG

Mr. Tim Limacher, a student at the High School of Mathematics and Science in Zurich, has successfully completed his internship at NOVAGEAR AG. He says: “I got the opportunity to apply and extend my theoretical knowledge in a specific project. I used various design and calculation tools for the development of a high-speed gearbox. This…